by Amber Lively

I grew up in a wonderfully matriarchal family structure.

My mother, grandmother, and great-grandmother all played a role in my upbringing. There were numerous skills and trades passed within four generations of women. Some of my favorite memories of my great-grandmother revolved around the sewing machine, as she sewed and mended everything that came across her table. My mother followed this tradition; she sewed many of my childhood clothes. My sister and I would always look forward to picking out patterns, fabrics, and threads for our wardrobe updates. Most of our dresses had hand-stitched labels that read, “Made With Love By Mom”, and I still smile thinking about those tags.

Between grade school and high school, the convenience of catalog ordering and the thrill of mall shopping took hold and more of my clothing started to have a company label instead of my mother’s hand-stitched tag. Years passed by, and at some point, I stopped thinking about the tags or who made my clothes.

Then, on April 24, 2013, as I treated myself to a shopping spree, I looked at the television mounted above the rack of clothes I was browsing and saw news of the Rana Plaza collapse in Bangladesh. This eight-story building was home to manufacturing facilities that supplied garments to fast fashion brands such as Joe Fresh, Primark, The Children's Place, Mango, Matalan, Bonmarche, and Benetton. The garments I was wearing, as well as the ones I was holding in that shop when I saw the news, were made in workshops like Rana.

The 2013 Rana Plaza garment factory collapse, killing more than 1,100 workers and injuring 2,600 more, is the apparel industry’s worst ever industrial incident (The Conversation, 2021).

Image Credit: Munir Uz Zaman/AFP/Getty Images

Half a world away, Rana Plaza and the garments produced within its walls had never crossed my mind. And that is the essential problem. When nearly all Western garments are produced abroad, we as consumers lose the connection to the process.

Spinning out of control

“When nearly all Western garments are produced abroad, we as consumers lose the connection to the process. ”

There are more opportunities for the supply chain to become less transparent, and less accountability for exploitive or unethical practices for brands. Fifty years ago, more than half of all garments purchased in North America were produced domestically. Many families, like my mother's, created their own dresses and work clothing, considering it an act of love for the household. With today's garment production, the thought of who made the clothes we are wearing isn't necessarily imparted upon us as consumers, thereby concealing the conditions in which garments are produced.

In the case of Rana Plaza, an inspection of the building a day before the collapse resulted in the building's closure due to structural cracks. Inspectors cited the top floors — those used for manufacturing — as being incorrectly permitted as the building's intent was for shops and apartments. Nevertheless, workers were forced to return the day after the building was officially closed only to have the structure collapse; presumably from the weight and vibrations of machines on the manufacturing levels. The owner of the building, along with several brands, retailers, and distribution companies that utilized the garment factories, were criticized for placing profits over the people who worked in the facility. More than 1,100 people lost their lives and another 2,600 people were injured in the Rana Plaza collapse, but many of the brands responsible have yet to commit to any actionable change regarding worker compensation or safety.

Despite such warnings, garment consumption habits continue to increase exponentially. Fast fashion has increased clothing cycles from two per year to new micro-cycles every 1-2 weeks. With the advent of online shopping through mega-platforms such as Amazon, consumers have access to inexpensive trends with free express shipping. It is very easy to find inexpensive garments that can be conveniently shipped to your door. For those who look at their “cost per wear”, a $10-20 item can feel justified with such a model. The numbers don't lie: people are buying clothing at record rates. In 2017, the World Resources Institute reported that people purchased 60% more clothing in 2014 than in 2000 but kept each garment only half as long as previous years.

Fast fashion brands use fine-tuned production and distribution models to dramatically shorten fashion cycles, sometimes getting a garment from the designer to the customer in a matter of a weeks instead of months. The number of fashion seasons has increased from two a year – spring/summer and fall/winter – to as many as 50-100 microseasons ( World Resources Institute, 2017)

Many, like myself, may be guilty of thinking that all of our pre-loved garments will find a new home through thrifting, but only about 20% of donated clothing make their way to a new home. Most clothing end up in landfills, and given that these items contain an abundance of synthetic fibers such as polyester and rayon, they will not biodegrade. Instead, they will continue to shed microfibers into the soil and waterways.

Since the Rana Plaza collapse, I have been learning the human and environmental costs of the fashion industry, which has consequently brought me back to those labels from my mother and great-grandmother’s handmade clothes. When I knew who was making my clothing, I took particular care of them. I mended holes, tears, and snags as soon as they occurred in order to lengthen the lifespan of the garment. I treated any potential stain on the spot, and I took care to wash them on the correct cycles. I wanted the love that my mother put into each garment to be reflected in how I wore it, and I was proud to know I had ownership in the creation of each piece.

“When I knew who was making my clothing, I took particular care of them. I mended holes, tears, and snags as soon as they occurred in order to lengthen the lifespan of the garment.”

Threading with care

As a consumer, I have a responsibility to know not just who made my clothes, but under what conditions those garments are produced. Now, I look at the websites of brands to see if they have published information on their corporate and environmental stewardship. Are they transparent about the wages they pay their workers? Are the facilities held to a standard that I would feel comfortable having a loved one work there? Does the company use harmful dyes? How do they dispose of the waste generated throughout the manufacturing process?

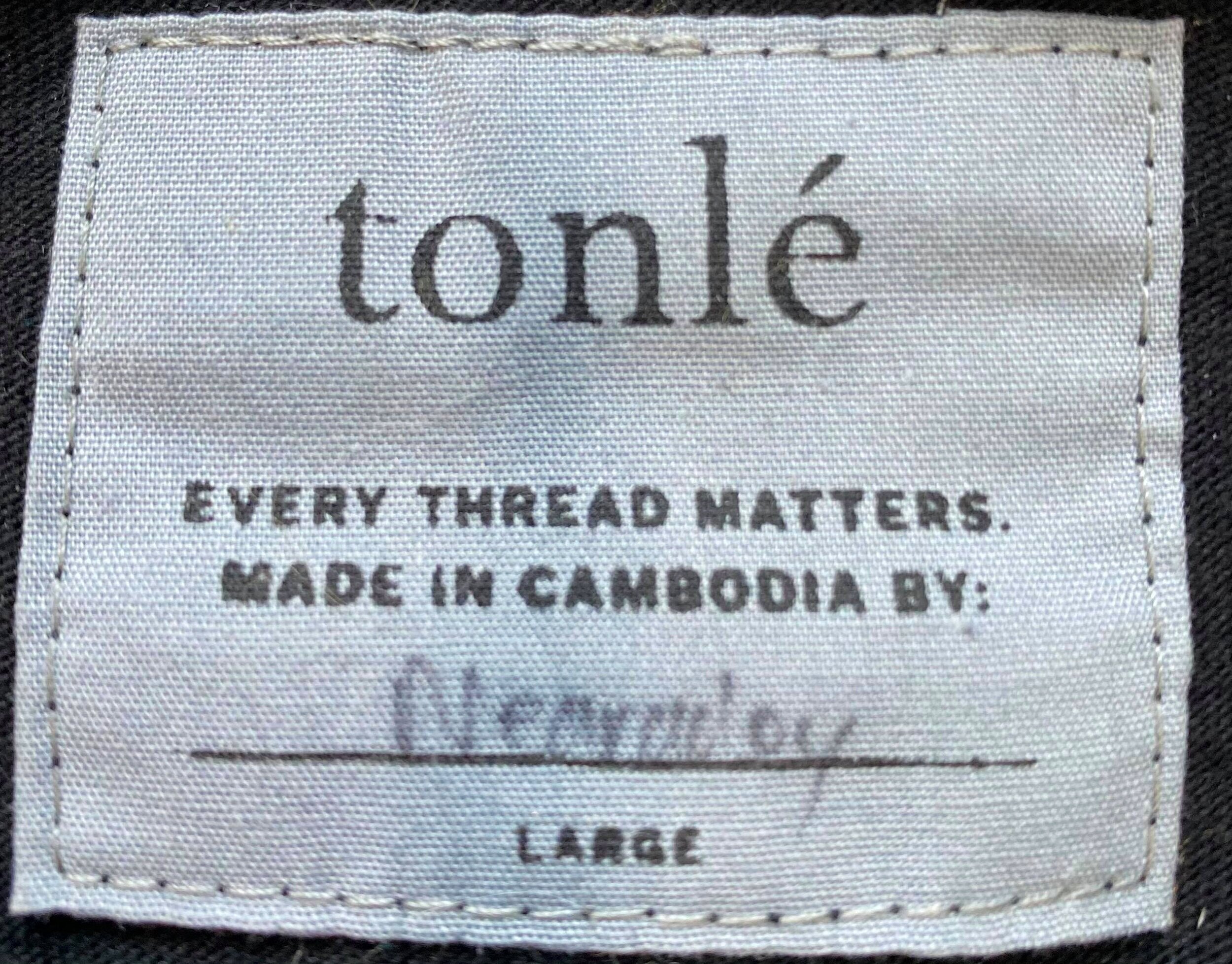

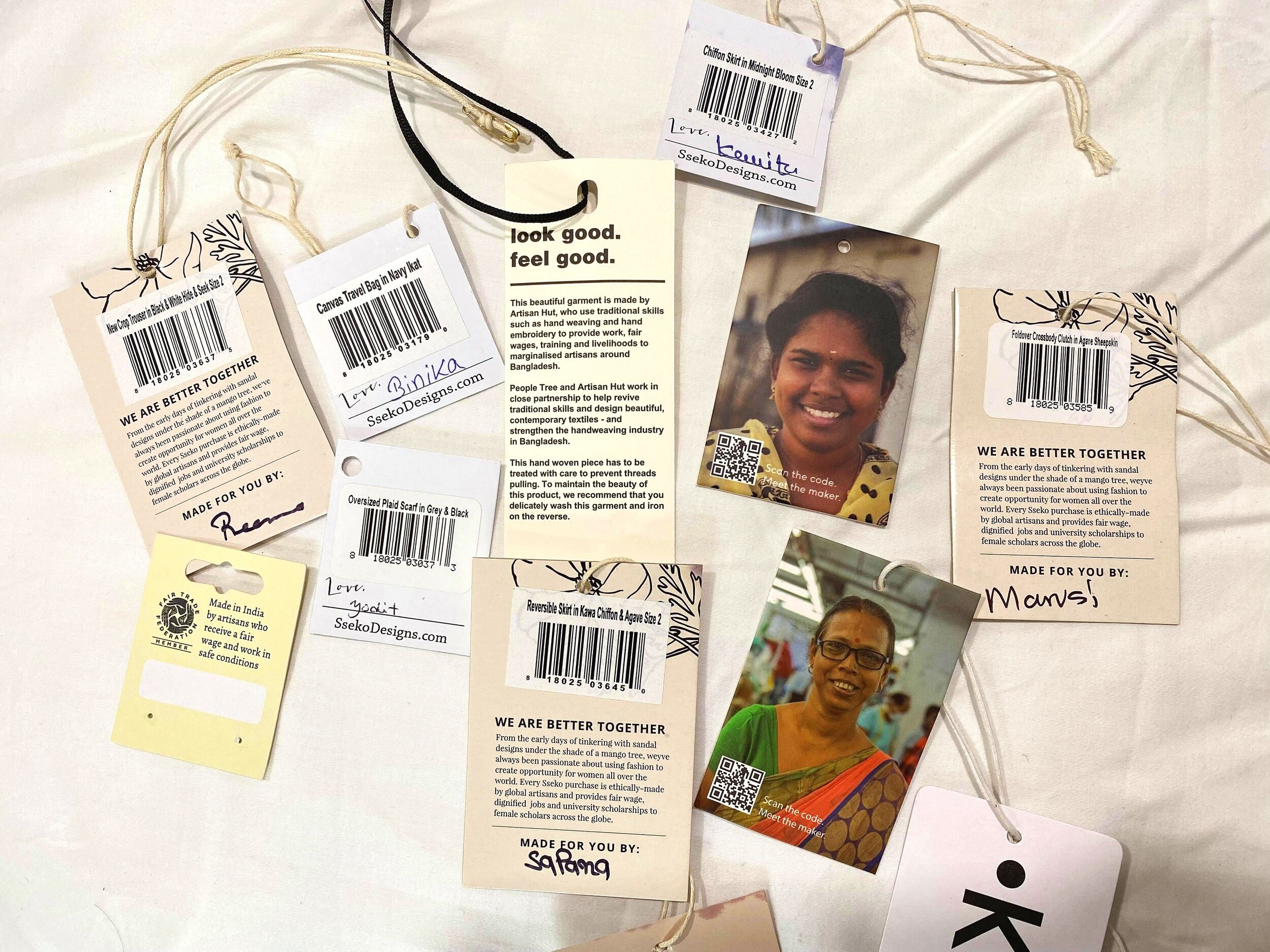

This may sound like a lot to ask, but most of this information is easily accessible on websites of clothing companies. Brands like People Tree, Tonle, Known Supply, Conscious Clothing, The Girlfriend Collective, and more have transparent practices available for consumers to read and feel the goodness that comes from their purchase. Just asking questions about the company and the people who are responsible for making my clothing has changed the way I think about my wardrobe all over again. A while ago, I needed a basic black t-shirt to replace an old Hanes one that had become threadbare from years of wear. I was excited to replace this beloved clothing with another made from a sustainable and ethical clothier.

As consumers, we all have the power to vote with our pockets, and support companies that invest in their workers and in the environment. Such actions send a strong message that these are the types of companies we want to endorse. It is true that items from some sustainable companies cost more than what may be found in many popular retailers or on Amazon, but that cost is an investment in the person and who made the garment.

If we circle back to the cost per wear, I've found that investing in quality pieces has also helped me live with less in my closet. I now wear each item way more frequently than their fast fashion counterparts. Why? Because they last longer. Because I have less “stuff” to sort through. When the up-front cost is higher, it makes me think about whether I actually need the item. Will it be something I want to wear more than 30 times? How about 50 times? Is it timeless or would I have not given it a second look two years ago?

What's incredible about slow fashion brands is that many of the pieces that I have in my closet have a label that includes the name of the person who made it. While it may not say “Made With Love By Mom”, it still makes me smile.

About The Author

Amber Lively is a resident of Sioux Falls, South Dakota, USA, where she lives with her partner and their two dogs. An avid environmentalist, Amber is passionately involved with several local and National nonprofits that aim to restore waterways and conserve wildlife. She also serves as President of her local chapter of Graduate Women in Science and uses her platform to promote underrepresented voices in STEM fields. In addition to advocating for slow fashion, Amber works to encourage sustainable actions and mindsets within her local community.